A survey and roundtable report asked more than 500 industrial companies to learn how they measured energy use and improved efficiency

IESO enlisted the expertise of CanadianManufacturing.com to develop a survey of more than 500 industrial companies that measured energy use across Ontario’s business landscape. We also conducted a series of round table discussions to identify common barriers to adopting energy efficiency regimes, and to gather anecdotal evidence from the experiences of small and medium-sized business operators in their journey to improve efficiency and mitigate energy costs.

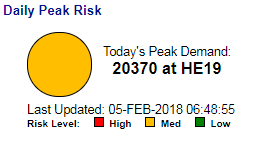

The first step towards creating an energy-efficient plant is awareness — understanding how energy is being used, and which equipment and processes are using the most energy. Armed with this knowledge, companies can target inefficiencies, find opportunities for improvement and establish a business case for energy projects that will reduce operating costs and improve performance.

Though an energy audit is key to pinpointing problems, lack of time and resources can be a challenge for some companies. It can be a time-intensive process that can take at least a couple of months to complete, depending on the size of the facility. However, firms don’t have to go it alone. A third-party typically conducts the audit, and there is funding available to help pay for some of the costs. The IESO’s saveONenergy program, for example, has an incentive that covers some of the cost of an energy audit. As businesses put more focus on saving energy, they are looking to companies like CompAir Canada to conduct these audits.

Energent can help turn your energy data into actionable knowledge! Read the full report here